As part of the Saline Festival on September 23rd and 24th, 2023, the Salzwirker-Brüderschaft im Thale zu Halle and the Hallesches Salinemuseum e.V. present the open-air exhibition "Brine, salt & boiling fires - The saltworks in the Halle valley" in the courtyard of the Saline.

The digital exhibition is presented here for an unlimited time period.

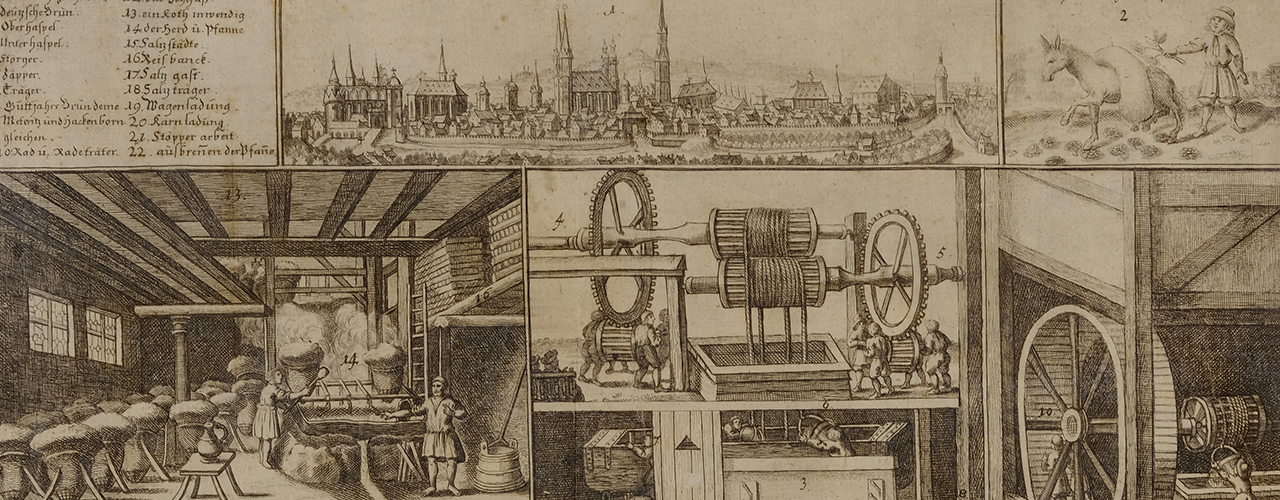

The focus of the exhibition is a copper engraving from 1670, printed in the book "Das Saltz-Werck zu Halle in Sachsen" by the salt count Dr. Friedrich Hondorff (1628–1694). The book and the engraving represent the first known collection of knowledge on the central work processes in salt production.

Take a journey back in time to the year 1670 and meet the salt count, the salt workers and the head boilers in their place of work.

E-Book „GeschichtenWissen – Aus dem Salzwerk im Thal zu Halle“

Interesting details not shown in the copper engraving are compiled in texts and stories in the accompanying e-book (in german).

Download E-Book (PDF)

Can be opened directly in the browser without an additional add-on.

Download E-Book (ePub)

Please note that an appropriate browser add-on is required here.

(Example: EPUBReader for Mozilla Firefox and Google Chrome)

My name is Dr Friedrich Hondorff, I am the son of a saltworks foreman and since 1660 the salt count in Halle on the Saale.

I invite you to a tour of the saltworks in the Thal of Halle!

The images on a copper engraving guide you through the workplace of the salt workers and boilermakers. Find out what a Haspeler does, who can become an Oigler and what cow’s blood has to do with it all.

The copper engraving shows the most important steps in salt production. It was printed in my book "Das Saltz-Werck zu Halle in Sachsen". I researched numerous documents and spoke to the salt workers. I wrote down my findings and published them in 1670. This was the first published work about the saltworks in Halle and its ownership structures describing the offices and professions of the people working in the saltworks as well as detailed summaries of the internal regulations and working methods.

E-Book "Guten Tag, ich bin der SALZGRAF!"

I tell details about my tasks as a salt count in the text "Guten Tag, ich bin der SALZGRAF!" in the e-book (in german).

By the way:

I studied philosophy and law in Jena and Rostock. After that I took over several offices in Halle’s city administration. In 1657 Duke August of Saxony-Weißenfels appointed me privy counsellor and three years later I became salt count. A kidney stone ended my life and my 34-year tenure as salt count in 1694.

With strength of arms on the cable winch

We Haspeler or reelers work in the German well and draw out the brine with two cable winches, the "Haspeln". Two men stand next to one another and turn the cable wheel. The winch draws a full bucket up and an empty one down via a rope. Then the first pair of men step back and two others take over. We take turns and thus conserve our strength. Because the upper wheel is built higher than the lower wheel, four men can work parallel on the left and right side of the well. We switch sides every day and workstations between upper and lower wheel on a weekly basis. As a result, no one is overburdened.

Shift work around the clock

Sunday at 5 p.m. the first team starts work on a long shift of eight hours. After an eight-hour break, the short four-hour shift and a break of the same length follow. We work around the clock at the German well and the Gutjahr well, so that 24 hours count as one workday. On Saturday the salt count and the head foremen make the work schedule. In a full week we work six days at a time. But last year this happened only 19 times. In the past, between 1589 and 1620, 50 full weeks a year was normal!

By the way:

We are 16 reelers and draw more than 12,000 buckets of brine from the German well in one day!

Read the Story here:

How Johann gets a job in the saltworks is told in the story "Johanns Weg zum Haspeler!" in the e-book (in german).

Pouring piecework

I work under the cable winch called the "Haspel". The full buckets come up out of the well with a bang. I pour them out and the brine flows into a reservoir called a "Kahn". The cable winch has a lot of force behind it and the people operating it cannot see or hear me. Iron hooks are attached to the "Kahn" so that they do not pull the buckets out of my hands by accident. The buckets are caught here and I can empty them more easily.

Filling with feeling

The "Kahn" of the German well has holes or taps on two sides so that they can be worked at the same time. When I put an empty bucket or Zober under the Kahn, I have to keep the order of the vats exactly. Then I pull out the wooden spigot, let the brine run out and plug it back in. It is important that we tap the brine at the same time, otherwise the salt content will not be divided equally.

Every drop counts!

We Störzer and Zäpfer make sure that no brine is spilled or waisted. We catch every drop in barrels and small tubs and pour it back. The quantities are calculated precisely and spread out precisely in the evaporating sheds. Nothing must be lost.

By the way:

Each Zober in the Thal is assigned to a well and evaporator so that nothing goes wrong. They have names like the fish, the cup, the windmill, the triangle or the Greek A.

Read the story here:

The Story “Die Bornfahrt 1662” in the e-book tells of a well visit (in german).

Legwork in the treadmill

There is an almost eight meter diameter wooden treadmill at the Gutjahr well to which a shaft with a rope and two buckets is fixed. Here we Radtreter are divided into groups of three workers each. Two of us are in the treadmill and walk. The third yells "Stop!" when a full bucket is up top. Then they stop and he tips the brine into the basin called the "Kahn". Then the two men turn and walk in the opposite direction and raise the second bucket. This goes back and forth until after twelve buckets positions are changed so that everyone takes turns in the treadmill and emptying the buckets.

Break room and call to work

At the Gutjahr well we work around the clock and have the same shifts as the Haspeler at the German well. Anyone who lives further away from the well stays in the Thal during their breaks in the rooms called the "Capitul". In the winter it is heated and there are chambers where one can sleep. But if workers live close enough to the German well or the Gutjahr well they can go home in the breaks and a runner calls through the streets and it resounds: "Hans, to the well for God’s sake!", so that nobody comes too late.

By the way:

Twelve Radtreter raise more than 6,000 buckets of brine a day from the Gutjahr well!

Read the story here:

The story „Der Gerenten-Streit“ in the e-book is about money (in german).

Keen eyes at work

We Oigler or foremen make sure that things run smoothly in the well. The laws and regulations in the Thal prescribe what is permitted and prohibited when drawing the brine. All salt workers take an oath to abide by these rules. We Oiglers make sure they keep their word. We reprimand them and settle disputes. In the worst case, we issue bans or punish their offences.

On the go day and night

You can find us in the wells around the clock; we supervise the workers and keep an eye on the equipment. The workers are not allowed to raise more than the planned quantities. The pans and buckets are calibrated and it is not permitted to use any other equipment. The workers should not spill any brine and at the end of the day all the containers - from the buckets to the boiling pans - should be completely empty.

Observing the condition of the buildings

If an Oigler discovers damage to a building, he reports it to the salt count and the Oberbornmeister or head foreman. The salt brotherhood must then take care of the repair work. We pass on information on any damage or ideas for improvements immediately so that wells remain in good working condition.

By the way:

Not everyone can become an Oigler. You have to own your own house and have citizenship rights in the city of Halle.

Read the accompanying text here:

The text "Hallo, ich bin Bornmeister!" tells you all about the foremens tasks in the e-book (in german).

Heavy transport on foot

Our main tool is a wooden pole that we call a „Baum“ that fits snugly through the openings on the Zober. A Zober filled with brine weighs more than 120 kg. About 2,700 of these are carried from the well to the evaporating sheds every day. A total of 52 Träger or porters are on the move around the clock. At the collecting tank, the "Kahn", we pick up the full bucket, lift it with the carrying pole and put it between the two of us on our shoulders. Then we carry our load through the Thal to the boiling shed, where the brine barrel protrudes slightly from the wall of the house. Here we pour in the brine, before we return to get the next full Zober. The two of us transport the brine from the well to the boiling shed about 100 times a day.

Health and safety thanks to strict regulations

The porters have strict orders and their own poles and responsibility for specific Zober and boiling sheds. If something gets mixed up, the boilers get too much or too little brine and cannot boil the amounts they are required to boil. These orders also regulate the carrying process. We alternate between left and right shoulders, as well as positions at the front and back of the pole. In this way we avoid strains and injury.

By the way:

Anyone who gets sick or old and frail still gets their wages, which we then call “Gerente”. From this Gerente he can hire a temporary replacement or "Zippelläufer".

Read the accompanying text here:

The text " Wir sind STEGESCHÄUFLER und SPULENZIEHER!" tells about the tasks of further salt workers in the e-book (in german).

Structure of the boiling sheds

Our workplace is a brick stove over which the forged boiling pan hangs. First we seal the edge of the pan all around so that no sparks fly up later. There is only an opening at one end. Then we pour about four buckets of brine into the pan and see if the pan is level. If necessary, we put bricks in the corners to make sure it is.

The "Big Fire" with 36 buckets of brine

We kindle a big fire and pour 21 buckets of brine out of the brine barrel. Then a bowl of cow’s blood is added and mixed thoroughly. We pour another 15 buckets and keep the fire on full heat. The cow’s blood ensures that the brine foams and is thus cleaned. We skim off the foam and let the fire continue to burn vigorously for an hour.

Three of us work together in the boiling shed: a head boiler and two workers. While the head boiler supervises the work and has the responsibility, the other two work the pan.

By the way:

Fire safety equipment is mandatory in every boiling shed: 1 ladder, 1 brass nozzle, 2 leather buckets and 1 poker.

Read the accompanying text here:

Who takes care of order and cleanliness in the saltworks tells the text "Hallo, ich bin FLÖßMEISTER!" in the e-book (in german).

Beer for the grain

Now we swing the beer pitcher over the pan and pour in the "Schwenke Bier". This makes the salt grainy. We use the fire hook to distribute the embers evenly under the pan and let the brine steep for half an hour. This is called „soocken“ or „stocking“. One of the workers called the Zustörerin or disrupter ensures that no closed salt cover forms. They "disrupt" the settling salt with a wooden spoon.

Filling in stages

In the meantime we have two salt baskets at the ready. They are shaped like closed funnels and fit into a wooden rack above the pan. With a wooden shovel we transfer the salt from the pan into the baskets. Every once in a while a swig of beer is given to the remaining brine, which is "gesoockt" and then shoveled into the salt basket. The salt is dried over the fire of the next filling pan, until the baskets are stored in another part of the boiling shed.

Regulations and use (per boiling pan)

In four hours we need to fill two salt baskets, then "a work of salt" is completed. At least 36 works of salt (72 baskets) are boiled in a 6-day week. For this we need 162 Zober of brine, which is about 1,300 buckets. We also use 16 pitchers of Schwenke Bier and 2 pitchers of cow’s blood.

By the way:

A pan lasts 20 to 22 full boiling weeks, a salt basket only 10 to 12 boiling cycles. Then they have to be renewed or replaced.

Read the accompanying text here:

Another task around the boiling fire tells the text "Hier wird die Pfanne ausgebrannt!" in the e-book (in german).

Loading for sale

The loaders in the saltworks bring the full salt baskets to the carts of the buying merchants, who we call salt guests. We take the salt and pour it out of the basket. Different loaders are responsible depending on whether it is a wagon, a cart or a sled. For transport by ship we fill the salt into barrels. Twelve foremen and ten workers are busy loading the wagons so that they can move on quickly and not block the narrow streets in front of the salt sheds. The size of the vehicle to be loaded determines our salary.

Securing the load

The salt is not only spread flat on the large transport wagons, it is also heaped upwards. Here we Stöpper or stuffers come into play, because it has to be protected from moisture and secured. We stuff straw around the edges of the load and cover the salt with a linen tarpaulin. Then we push hazelnut wood rods around the edges of the load and the wagon and tie it down with a long cord called the Lauf-Seil or "running rope". Thus the load cannot shift on the uneven roads. Six foremen and six workers work together in one shift with the loaders. All are paid directly by the “salt guest”.

By the way:

The foremen collect and keep the money earned until the end of the week. First the workers and boys get their wages, then the material stocks are replenished. If something is left over, the foremen divide it among themselves.

Read the story here:

The story „Das Geisterschiff“ in the e-book tells why strange things suddenly happen in the valley (in german).

Clean goods

I came to Halle via the salt road from Dresden. I buy the salt I need from the saltworks foreman. Unfortunately, the open fires in the boiling sheds leave an unsightly layer of soot on the dry salt. I sweep the goods thoroughly with my broom, count the units of salt and let the loaders bring them to the cart.

Fixed prices

In the city, the price of salt is the same for all salt workers, foremen and salt guests. The salt count and the head saltworks foreman determine the price and post it publicly. The salt price is the sum of the costs for the brine and the boiling of the salt, local taxes, the average fixed costs in the boiling sheds and profit share for the salt workers. I pay the foreman an „Ausschlage-Geld“ or deposit for each work of salt. The loaders and stuffers receive their wages from me directly according to the size of my wagon.

Standardised quality

The units of salt from each salt shed are the same size. As a salt guest, I can rely on that. The salt count and head saltworks foreman are in the salt sheds on a regular basis and ensure that every work of salt corresponds to the calibrated salt measure.

By th Way:

It is illegal to intercept me outside the city gates and to interfere in my business with the seller I came to buy from. Competition between different salt producers like it is the case in the 21st century is not (yet) an issue in the saltworks.

Read the story here:

What a boy experiences on his first visit to Halle on the Saale is told in the story „Konrads erste Salzreise“ in the e-book (in german).

Imprint

Project participants: Hallesches Salinemuseum e. V., Salzwirker-Brüderschaft im Thale zu Halle

Exhibition concept: Steffen Kohlert

Design and realization of the digital exhibition: LIXX Consult & Ventures GmbH

Texts: Tina Kaltofen

Translation: Andreas Hemming

Expert advice: Rüdiger Just

The exhibition is sponsored by the city of Halle (Saale) and the Saalesparkasse

Thanks for permission to use images and sources to the following institutions:

Salzwirker-Brüderschaft im Thale zu Halle; Digitales Bildarchiv Hallesches Salinemuseum e.V.; Stadt Halle (Saale), Fachbereich Kultur

We have tried to the best of our knowledge to clarify the rights for all illustrations in the exhibition and to indicate the correct sources. If you notice any discrepancies, please send an email to: halloren(at)salinemuseum.de

Figure 1: Copper engraving: Die Salzgewinnung. Aus Friedrich Hondorff: Das Saltz-Werck zu Halle in Sachsen befindlich, Halle 1670

Figure 2: Dr. Friedrich Hondorff (1628–1694): Johann Christoph von Dreyhaupt, „Pagus Neletici et Nudzici […] Description of the […]“, Part 2, 1750, Tab. XXXIV S. 761, https://commons.wikimedia.org/wiki/File:Friedrich_Hondorff.png

Figure 3-13: Details from the copper engraving: Die Salzgewinnung - Friedrich Hondorff